Benefits of Silicone Insulated Wire or Cables

The thermal range of silicone rubber insulated cables is exceptional, ranging from -90 °C to 300 °C. In addition to greater heat resistance, silicone insulated wires also demonstrate better flexibility and maneuverability in tight spaces compared to PVC insulated wires. Here you’ll find out more about different types of silicone insulated wires and their benefits for tough industrial applications.

Types of Silicone Insulated Cables

Silicone insulated cables come in many forms. Here is an overview of the most common types.

Tuffsil

- “Tuffsil” insulation with standard silver-plated conductor

- High flexibility

- High voltage: 600 VDC through 100 KVDC

- High temperature: 55 to 200 °C (250 °C intermittent)

- 24 AWG through 1 AWG conductors

UL 3239

- High flexibility

- 24 AWG through 10 AWG conductors

- Passes VW-1 flame test

- High voltage: 5 KDVC through 60 KDVC

- Corona and ozone resistant

UL 3616

- Corona and ozone resistant

- High flexibility

- Meets VW-1 flame test

- 8 AWG through 2 AWG conductors

- High voltage: 20 KVDC through 60 KVDC

Sil-KOAT

“Sil-KOAT” silicone insulation provides a jacket suitable for bonding with various potting materials and adhesives. Other highlights of this product line include:

- Ozone and corona resistant

- Small diameter

- 28 AWG through 20 AWG conductors

- High voltage: 1 KVDC through 30 KVDC

- High temperature: -55 to 200 °C

- High flexibility

- Reference: MIL-W-22759

- Nomex braid available for abrasive applications

Benefits of Silicone Insulated Wire

Silicone insulated wires offer a variety of advantages.

Flame Resistance

The composition of silicone makes silicone insulated wires the best choice for protecting circuit integrity in case of a fire. Silicone is flame-resistant, providing enough time for the fire to be put out—other types of insulation would quickly melt. Extreme flame resistance is the primary advantage of silicone insulated cables over other types of insulation.

Thermal Resistance

What makes silicone insulated wires premium cables is their versatility and thermal resistance. Silicone insulated wires resist very high and low temperatures. The silicone wire temperature rating of industrial-grade insulation can be as high as +572 °F (+300 °C) and as low as -130 °F (-90 °C). The temperature rating for general-purpose silicone rubber insulation can be as high as +392 °F (+200 °C). Silicone rubber insulated cables maintain excellent flexibility and transmission properties regardless of temperature.

Thermal Aging Resistance

An electronic cable’s transmission capacity is determined by its allowable temperature. If the insulating material operates at the allowable temperature, the cable can safely work for a long time. If the operating temperature of the cable is too high, the insulation will degrade faster and shorten the cable’s lifespan. Silicone can effectively resist any aging when exposed to high temperatures.

Chemical Resistance

Silicone rubber insulated cables have a protective coating that makes them impervious to various chemicals and substances—like gas, oil, and ozone—that would damage cables insulated with PVC. Silicone cables are extremely dependable if you work in an environment with volatile chemicals.

Chemically Inert

Silicone is a non-reactive inert polymer, so it can be used in food and beverage processing without risk of contamination. They are also better for the environment than plastics and easy to clean so that sanitation standards are met.

Fit for Outdoor Use

Silicone insulated wires are a top choice if you need a material that can withstand elements such as water and heat. Silicone insulated cables can be exposed to harsh outdoor conditions, such as on rooftops subjected to constant heat from the sun.

Compression Resistance

Even after prolonged pressure exposure, silicone insulated wires retain their original shape. If you need cables that can bounce back after being subjected to pressure, silicone cables are the optimal solution.

Choose Connectronics for Quality Silicone Insulated Wires

Connectronics provides customers with reliable, high-quality connector products. We design and manufacture silicone insulated wires for various industrial applications, including those in the aerospace, medical, oil exploration, nuclear, and stage lighting industries. Contact us or request a quote today to see how our silicone insulated cables can support your needs. For more information you may also contact our sister company Wiremax at www.wiremax.com.

What Is a Cable Jacket?

Here we’ll discuss other differences and similarities between thermoplastic and thermoset materials, as well as how they impact the performance of cable jackets.

Cable Jacket Types

Cable jackets protect the conductor core and insulation of cable assemblies from environmental damage. Certain materials suit different levels of protection and applications.

Thermoplastic

Here are the most popular thermoplastic materials for cable jackets.

- Polyvinyl Chloride (PVC): PVC cable jackets can withstand heat, sunlight, weathering, oils, acids, and physical abrasion, making them an excellent choice for outdoor cable jackets.

- Polyurethane: Polyurethane jackets are effective at resisting chemicals and oils. They can also be formulated to resist oxidative damage, ozone, and open flames.

- Chlorinated Polyethylene (CPE): CPE can be formulated in both thermoset and thermoplastic varieties. Thermoplastic CPE can resist heat and flame damage, weather elements, oxidation, and oils.

Thermoset

These are the most common thermoset material options for cable jackets.

- CPE: Compared to thermoplastic CPE, thermoset CPE’s cross-linked structure offers better protection from ozone and ultraviolet damage. When specially formulated, it withstands solvents, bases, and acids as well as long-term water immersion.

- Ethylene Propylene Rubber (EPR): This synthetic rubber is derived from EPR insulation. It can withstand high temperatures as well as temperatures down to -60 °C. EPR can also be designed to resist flames.

- Neoprene: Neoprene is a resilient synthetic rubber that offers good resistance to physical wear, oxidation, sunlight, heat, and cold temperatures. It’s a popular choice for protecting mine trailing cables, dredge cables, and cables in other rugged environments.

Properties of Cable Jackets

Consider which protective properties you need for your cable jackets. Your choice of material will determine which of the following characteristics your cable assembly will have:

- Abrasion resistance

- Chemical resistance

- Deformation resistance

- Flame resistance

- Flexibility and stability at low or high temperatures

- Oil resistance

- Moisture resistance

- Resistance to heat aging

- Weather resistance

By determining which protective characteristics are most important, you can select the best thermoplastic or thermoset cable jacket material to protect your assembly for years to come.

Choose High-Quality Cable Jackets From Connectronics

If you’re ready to select a cable jacket for your particular application, we’re here to help. At Connectronics, we specialize in designing and producing custom, high-performance cable jackets. We manufacture high-voltage and high-current connectors, cable assemblies, wire harnesses, and more. We’re ISO 9001:2015 certified and meet the requirements of AS9100D quality management. Contact us today to learn more about our capabilities, or request a quote to start your custom order.

Choosing the Right Rugged Connector for a Harsh Environment

As technology continues to advance, it finds new applications in ever more challenging environments. In these extreme conditions, regular connectors won’t do. Harsh connectors feature a robust design with ruggedized housings to protect against water ingress, rough handling, and other tough environmental conditions.

Choosing the Right Rugged Connector

There are different harsh environment connectors designed to meet the demands of different industries, from military and marine to transportation and medical. To determine which one is best for your application, you need to understand the environment, the connector’s function, and the connector’s strengths and limitations. When choosing a rugged connector, consider the following:

What’s the Application?

Will your connector be exposed to extreme temperatures, water, pressure, altitude, vibration, or salt? Does it need to meet specific industry standards? Does it require EMI shielding? Answering these questions based on your specific application will narrow down your choices and make it easier to select the proper connector.

Connector Basics

Consider the size of the contact and wire as well as how much electrical current an individual contact can carry. The voltage rating is dependent on insulation materials, insulator geometry, and contact spacing.

Sterilization

For medical and laboratory settings, it’s important to understand how the connector will be sterilized: chemically, with steam, or with radiation? Your connector may need to be able to resist corrosion, moisture, or pressure during the sterilization process.

Connector Reliability

If your connector will be mated and unmated frequently, choose one that’s rated for at least twice the number of mating cycles expected. Also consider the connector’s reliability in terms of temperature resistance, sealing, and durability.

Connector Materials

The material you choose is a matter of budget, application, weight requirements, and desired lifespan. For durability, brass connectors with nickel or chrome plating and stainless steel are a go-to choices, while plastic is reserved for disposable and short-term applications. Aluminum is a lightweight choice that’s also good for miniaturization.

Size

Smaller is generally better, but small connectors still need to hold up in the given environment. Pin size affects how much power can be carried, making it a key consideration when determining connector size, along with termination methods, pin count, current capabilities, voltage, and more.

Key Features & Benefits of Harsh Environmental Connectors

Rugged connectors are built to protect against several environmental conditions, including:

- Moisture. Rugged connectors protect against rain, humidity, vapor, and submersion in water.

- Dust. Dirt and debris are present in many outdoor and industrial settings, which is harmful to electrical systems.

- Extreme Temperatures. Both heat and cold can damage technological components.

- Explosive Environments. Certain settings may contain combustible gas, mist, or dust, which can lead to an explosion.

- Rough Handling. Power and data connection can be compromised after connectors are dropped, dragged, or exposed to vibration.

- Pressure. Marine and aerospace applications are often exposed to pressures reaching 9,000 psi, or very low pressure at altitude necessitating the use of rugged connectors.

- Salinity. Rugged connectors can prevent corrosion caused by salty air or water.

Key features of rugged connectors include:

- IP Rating. The level of water or dust ingress protection you need depends upon the situation. Medical and food processing applications often require an IP69K rating, which ensures protection against dust as well as high-pressure, high-temperature spray down at close range.

- Locking/Coupling. There are a variety of mechanisms available, from ring and twist locking to threaded, bayonet, push-pull, quick disconnect, and more. Harsh environments require reliable locking and coupling mechanisms.

- Housing and Insulation. A corrosion-resistant metal housing can protect against extreme temperatures, dust, and moisture, while plastic composite housings offer more flexibility with a lighter weight. The insulation material must be able to withstand the operating voltages.

- Seals and Grommets. For a firm, watertight seal, rubber seals can be used inside the coupling.

Rugged Connectors from Connectronics

At Connectronics Corp., we design and manufacture specialized connectors and interconnection systems for clients in a wide range of industries. Since 1988, we’ve established ourselves as a trusted partner for versatile and reliable high-voltage, high-current, underwater, and other harsh environment connectors.

We are an AS9100D and ISO9000-2015 certified company with more than 300 years of combined experience in avionics, aerospace, nuclear, underwater, radar, oil exploration, stage lighting, and other fields. This makes us uniquely equipped to help you identify the ideal solution for your application. Contact us to learn more about rugged connectors, or request a quote for your project.

Guide to Types of Cable Connectors

Electrical connectors are components that join electrical circuits, making electronics easier to manufacture and assemble. They facilitate design and modification flexibility and can be permanent or temporary. There are many types of connectors used with circuits throughout a wide spectrum of industries, ranging from communications to computers, industrial machinery, and more.

Electrical Connector Types

Since electrical connectors are used in such a wide array of products, they come in many varieties. Some of the most commonly used types include:

- Audio: Both digital and analog connectors are used in applications ranging from home theaters to professional audio equipment. Most audio connectors are easy to use and don’t feature release tabs, latches, or thumbscrews.

- Centronics: These standard parallel interface devices connect printers, portable disc drives to computers, and others. They are named after the first printer that used them.

- DB style: D-subminiature or D-sub connectors are commonly used in computer, audio/video, and data applications. Its name comes from its trapezoidal shape. Most DB connectors feature two rows of pins.

- Digital video: These connectors deliver high quality video signals using TMDS to transmit large amounts of data from a source to a display.

- DIN: Named for a German manufacturing industry standards group, this type of electrical connector features a circular pin pattern. It is widely used with computer keyboards, MIDI instruments, and similar specialized equipment.

- Fiber and networking: Fiber-optic connectors precisely align microscopic glass fibers to facilitate communications. There are many types of these connectors available, all sharing similar design characteristics.

- Firewire: Also called IEEE 1394, these devices are typically used to add peripherals to a computer, such as connecting an external hard drive. They deliver high transfer rates of up to 800 Mbps.

- High Voltage: H.V. connectors up to 100,000 volts are available while the average H.V. ratings are typically below 30,000 volts.

- Internal: Internal connectors, such as socket connectors, are located inside computer cases. They mate with pins arranged into a header, which is built into a circuit board. Power connectors are another type of internal connector. They distribute power to a computer’s internal devices.

- Modular: Commonly used for data networks, telephone systems, or low-speed serial connections, these connectors are inexpensive and simple to install. They feature a clear, plastic body and a tab that locks them into place when connected.

- Power: Power connectors get plugged into wall receptacles and provide power to a device. They are suitable for many types of electronics and can carry either an alternating or direct current.

- SCSI: Small computer systems interface connectors join devices with computers. They work by connecting all devices to a central bus that is controlled by a host controller, typically built into a motherboard.

- USB: Universal Serial Bus ports are standard cable connection interfaces for many consumer electronic devices. USB ports allow devices to transfer digital data.

- Video: Digital video connectors deliver the highest quality video signal using TMDS technology. Large amounts of digital data can be transmitted in high quality.

Industries for Cable Connectors

With such a variety of cable connectors available, it’s no surprise that they are used throughout many industries, including:

- Military & defense: Throughout this industry, soldier-worn defense technology has influenced the demand for smaller-sized connectors. New designs have increased connector ruggedness and throughput while decreasing weight. This is important for wearable devices that need to function reliably in harsh environments while being as compact as possible.

- Oil & gas: The oil and gas industries require rugged, explosion-proof connectors for applications such as petrochemical plants, downhole and subsea, as well as topside drilling.

- Energy & power: Cable connectors in this industry must be designed to withstand incredibly demanding environments and temperature extremes. They also need to be resistant to moisture and humidity. Applications include wind, solar, and other types of energy production.

- Submarine communication: Throughout this industry, cable connectors are used in temperature cycling and deep sea applications. They must be built to withstand seawater corrosion, shock, and high levels of pressure. High pin density and reduced size are important characteristics for connectors used throughout this industry.

Connectronics for All Your Cable Connector Needs

Cable connectors come in many varieties and are used throughout a number of industries. There are many highly demanding applications for cable connectors that require ruggedly designed products able to withstand challenging environments. Connectronics provides reliable, high-quality connectors for industries ranging from aerospace and nuclear power to medical, oil exploration, and more.

Visit our product catalog to discover the connectors we offer and contact us with any questions. To get started on your cable connector solution, request a quote today.

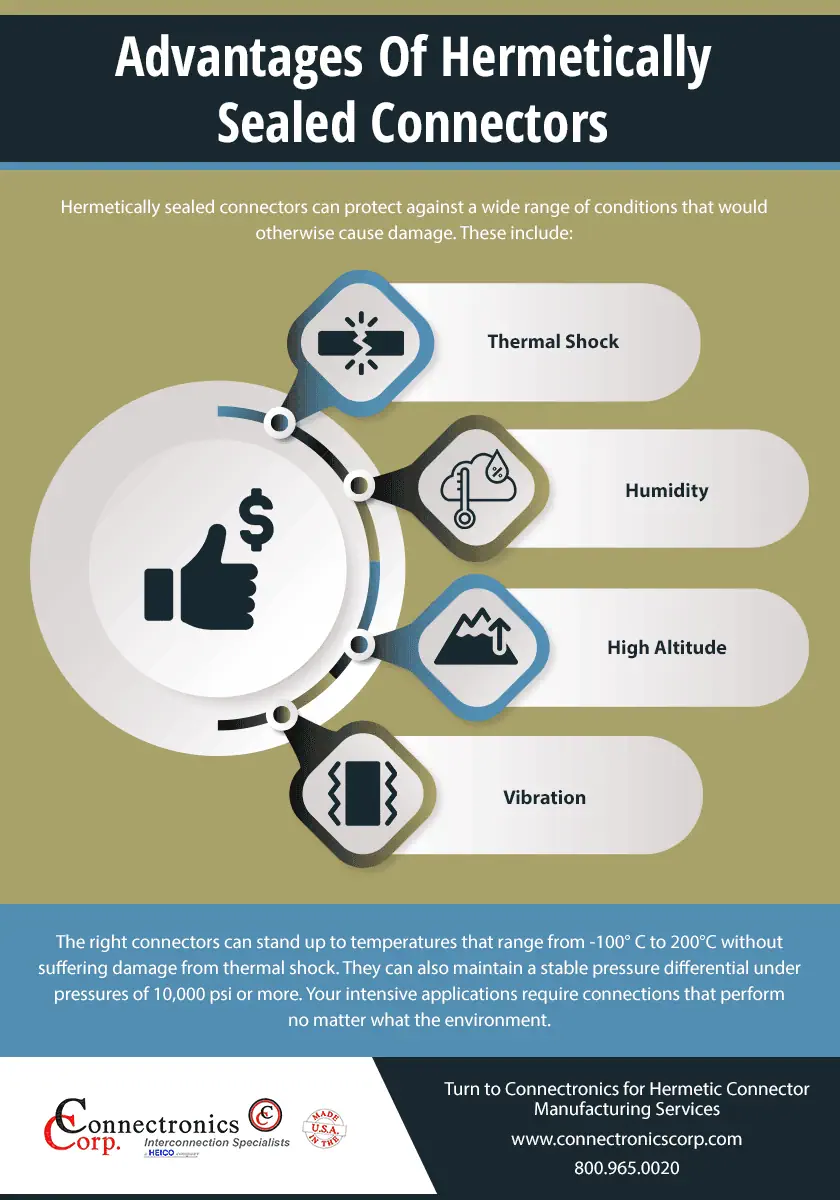

What Are Hermetically Sealed Connectors?

In extreme environments, connectors need extra protection. Various applications within the military, offshore, commercial, and industrial industries are exposed to harsh conditions such as high pressures and altitudes, temperature variations, extreme depths, corrosive materials, moisture, vibration, and more. Hermetically sealed connectors are specially designed to stand up to these and other challenges.

Hermetic connectors prevent air, gases, and liquids from entering the vacuum-sealed interior. In testing, they must be able to withstand pressures of 10,000 psi and higher while ensuring a stable pressure differential both inside and outside the assembly. They must also show no detectable gas or fluid leakage.

Advantages of Hermetic Connectors

Hermetically sealed connectors can protect against a wide range of conditions that would otherwise cause damage. These include:

- Thermal shock

- Humidity

- High altitude

- Vibration

- Extreme temperatures

The right connectors can stand up to temperatures that range from -100° C to 200°C without suffering damage from thermal shock. They can also maintain a stable pressure differential under pressures of 10,000 psi or more. Your intensive applications require connections that perform no matter what the environment.

How Are Hermetically Sealed Connectors Constructed?

When constructing hermetically sealed connectors, the connectors can use stranded or solid plated copper conductors, as well as insulated conductors. They may also contain brass, copper, or nickel iron pin contacts and fiber optic cables. Most are made of durable metals such as stainless steel, glass, and nickel iron, as these materials are capable of withstanding harsh environments. If weight is a concern, aluminum alloy shells can be used, which can reduce the weight of the connector significantly.

Most hermetically sealed connectors are glass sealed. This is because glass creates a rigid form that the metal shell compresses against, resulting in a hermetic seal. The glass is bonded to and provides support for the contacts. In some cases, glass can create excessive weight. In these applications, epoxy seals are used instead.

Applications of Hermetically Sealed Connectors

Many industries and applications rely on various measuring, sensing, and control systems for their operations. From navigation systems and power generation to medical implants and laser technology, these systems require components that can operate in extreme environments while retaining their original properties and offering reliable, error-free performance. Hermetically sealed connectors stand up to some of the most demanding applications.

Industries that benefit from hermetically sealed connectors include:

- Military/aerospace/defense

- Transportation

- Energy production

- Industrial

- Medical

Hermetically Sealed Connectors from Connectronics

The right hermetically sealed connectors can stand up to the stresses of your application. At Connectronics, we design and build hermetically sealed connectors capable of withstanding a wide range of harsh conditions. Our state-of-the-art environmental and electrical testing equipment allows us to test all of our connectors to ensure they meet the requirements of your application while providing reliable operation and long service life. To view our product offerings, visit our product catalog. For help finding the best hermetically sealed connector for your unique requirements, contact the experts at Connectronics today, and we’d be happy to discuss your application.

A Year in Review: Connecting the Events of 2016

Our focus this year was to continue to meet the high tech needs of the military and aerospace industries as we outlined in our ‘16 Outlook. At the beginning of the year, we announced the expansion of our product lines for more technologically advanced electronics. These new products have been incorporated into systems for aerospace, avionic, medical, fusion power, and many more industrial applications.

To continue to meet the demands for our connectors, our expansion plans were in full gear. We gave you a glimpse into our new production capabilities and the construction of our new building to house additional manufacturing operations. Through all the construction and mayhem of activity at our facility, we didn’t forget what has made us a leader in supplying reliable and robust connectors—customer satisfaction. We reiterated our leadership in our August blog. Our impeccable reputation is strengthened by our satisfied customers. From our high-quality connectors and interconnection systems to our dependable customer service, Connectronics delivers an unmatched customer service experience with each year topping the last.

In the past 12 months, we have continued our niche—manufacturing specialized high voltage connectors, high current connectors, underwater connectors, and cable assemblies that provide outstanding reliability and operation. Our experts continued to work with professionals in the fields of avionics, analytical instrumentations, medical devices, electronics, aerospace, and nuclear – just to name a few – to meet the needs and expectations of their final products.

2016 was a great year for us, and we are looking forward to continuing to exceed our customer’s expectations in 2017!

From all of us at Connectronics to all of our customers and contacts in the industries we serve, wishes for a Happy Holiday season and a healthy New Year!

Looking for a connector over the holiday season? Find the latest on our Twitter, LinkedIn, or contact us today!

Demanding Underwater Applications Require Reliable Underwater Connectors

As we know, water and electricity don’t mix. In fact, it is a deadly and disastrous combination; however, there are many applications that require electrical equipment to be in or near water. It is imperative that the right equipment is used to provide effectiveness and safety as a result of this factor.

One of our most specialized cable and connector series is designed and manufactured to

It is our work with numerous industry professionals that allows us to understand the specific and precise needs of working in a water environment. In a previous post we touched on our partnership with Yellow Springs Instruments (YSI). YSI develops global water monitoring solutions for clients concerned with climate change, drought, floods, clean drinking water, healthy ecosystems, and storm water runoff. Our 20-year connection (pun intended) has enabled YSI to develop instruments and data collection platforms for environmental testing and monitoring.

In order for these instruments to work effectively, the connectors must be secure and reliable. That is why YSI has chosen Connectronics as a partner. Our connectors can meet the needs of demanding underwater conditions. The cables have PVC insulation, a foil shield, polyurethane jacket and the plug, itself, is insulated with neoprene rubber. With a proper seal, the glass-filled epoxy, insulated receptacle, and stainless steel connector all work together to ensure that the connections are protected against water infiltration.

Applications for YSI and Connectronics equipment hit close to home as Ohio faces water

crisis’ such as blooming algae that threatens the water in Lake Erie. Last year was the first year the local area started to monitor the

As the old saying goes, “Water, water everywhere but not a drop to drink.” With the monitoring solutions of YSI and the interconnection components supplied by Connectronics, we feel confident that reliable and valuable information will be available to scientists, officials, and policymakers for a solution to keeping the water in oceans, streams, and lakes safe.

For further information on our products and services that we offer give us a call at 800-965-0020.